Infrared thermal imaging technology opens a new horizon for photovoltaic detection

As the global demand for renewable energy continues to increase, the application of photovoltaic power generation systems is becoming more and more widespread. However, photovoltaic modules may experience various faults in long-term operation, such as hot spot effect, hidden cracks, junction box failure, etc. These problems not only affect the power generation efficiency of the photovoltaic system, but also may cause safety hazards. As an efficient and non-contact detection method, infrared thermal imaging technology has shown strong advantages in photovoltaic detection. This article will explore the application of infrared thermal imaging technology in photovoltaic detection and reveal how it provides a new perspective for the maintenance and optimization of photovoltaic systems.

Common faults and their effects in photovoltaic systems

Hot spot effect

The hot spot effect refers to the high temperature area generated by some battery cells in photovoltaic modules due to local shading, dirt or damage, resulting in reduced efficiency and even fire.

Hidden cracks

Hidden cracks refer to tiny cracks inside photovoltaic cells, which are usually difficult to detect with the naked eye, but will lead to reduced battery performance and shortened life.

Junction box failure

The junction box is a key component of photovoltaic modules. Its failure may cause current interruption or short circuit, seriously affecting system operation.

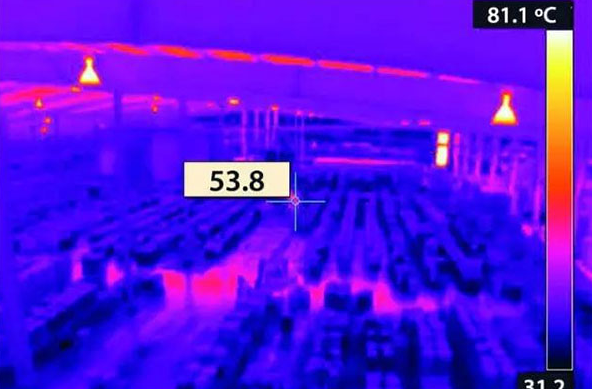

Application of infrared thermal imaging technology in photovoltaic detection

Hot spot detection

Infrared thermal imaging technology can quickly and accurately detect hot spot areas on photovoltaic modules. Infrared modules are the core of infrared thermal imaging technology. Through thermal imaging images, inspectors can intuitively identify high-temperature areas and take timely measures to remove obstructions or replace damaged components to avoid the impact of hot spot effects on the system.

Hidden crack detection

Although hidden cracks are difficult to detect through conventional visual inspections, infrared thermal imaging technology can identify hidden cracks by capturing areas with abnormal temperatures. Inspectors can use thermal imaging to analyze the location and extent of hidden cracks and make necessary repairs or replacements to ensure the normal operation of photovoltaic modules.

Junction box fault detection

Infrared thermal imaging technology can quickly detect the temperature distribution of the junction box and identify the fault area caused by poor contact or overheating. It can effectively avoid the risk of current interruption and short circuit, and improve the safety and reliability of the photovoltaic system.

Large area scanning

Infrared thermal imaging technology can quickly scan large-area photovoltaic power stations and comprehensively detect the temperature conditions of each component. This large-area coverage detection method can significantly improve detection efficiency, reduce downtime, and improve overall operation and maintenance effects.

Practical application cases of infrared thermal imaging technology

Case 1: Hot spot detection of large photovoltaic power stations

A large photovoltaic power station uses infrared thermal imaging technology for regular inspections. During the inspection, multiple hot spot areas were found. The inspectors quickly located and cleared the obstructions based on the thermal imaging images, and replaced some damaged components to ensure the efficient operation of the photovoltaic power station.

Case 2: Hidden crack detection of distributed photovoltaic systems

A distributed photovoltaic system operator uses infrared thermal imaging technology to detect its rooftop photovoltaic components. Through thermal imaging images, the inspectors identified multiple hidden crack areas and replaced the components in time, preventing the hidden cracks from further expanding and ensuring the long-term stable operation of the system.