When choosing a thermal imager, you need to consider the specific application scenario (such as industrial detection, security monitoring, medical diagnosis, etc.) and budget. The following are key factors and analysis:

I. Core performance parameters

1. Temperature resolution (NETD)

Definition: The ability of the instrument to detect subtle temperature differences, in mK (milliKelvin). The smaller the value, the higher the sensitivity.

Application matching:

Industrial precision detection (such as semiconductors, electronic components): ≤50mK is required to ensure the capture of tiny thermal anomalies.

Building energy saving/security: Usually 100-200mK can meet basic needs.

Note: Instruments with low NETD perform better in weak temperature difference environments (such as human body temperature monitoring).

2. Spatial resolution (pixels)

Definition: The number of pixels of the thermal imager (such as 320×240, 640×480) determines the image clarity and long-distance detection capabilities.

Formula reference: Minimum detectable target size = distance × pixel spacing (generally manufacturers will provide "spatial resolution (IFOV)" parameters).

Example:

640×480 pixel model: suitable for long-distance detection (such as power towers, high-altitude equipment), can see details clearly.

240×180 pixel model: suitable for close-range use (such as circuit board detection, building door and window air leakage), more cost-effective.

3. Temperature measurement range

Classification:

Low temperature section: -40℃~150℃ (suitable for human body temperature measurement, food cold chain, biological research).

Medium temperature section: -20℃~600℃ (industrial equipment detection, building insulation, photovoltaic hot spots).

High temperature section: 200℃~2000℃ (metallurgy, casting, volcano monitoring and other extreme environments).

Key point: When selecting, it is necessary to cover the target maximum temperature and reserve 20% margin to avoid over-range damage to the instrument or data distortion.

2. Function and applicability

1. Imaging mode and color palette

Imaging mode:

Fusion mode: The thermal image and the visible light image are superimposed to facilitate the rapid positioning of the target (such as the correspondence between the power equipment number and the hot spot).

Picture-in-picture mode: The local area displays the thermal image and visible light details at the same time.

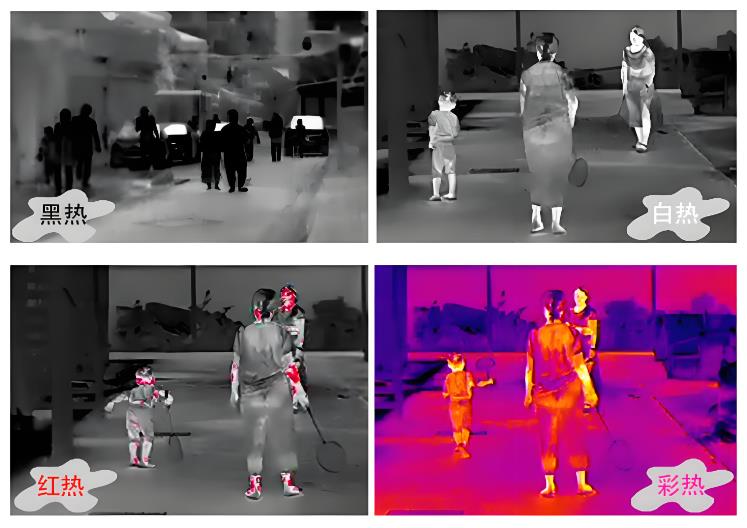

Color palette: Different color schemes (such as iron red, rainbow, and white hot) are adapted to different scenes:

Iron red/white hot: suitable for industrial detection, and the high temperature area is eye-catching.

Rainbow: suitable for scientific research analysis, and the color gradient is more delicate to show the temperature distribution.

2. Lens and field of view (FOV)

Lens type:

Fixed focus lens: low cost, suitable for fixed distance detection (such as online monitoring of production lines).

Zoom lens: supports long-distance zooming and flexibly adapts to different detection distances (such as handheld devices for patrol personnel).

Field of view: Wide angle (such as 90°×60°) is suitable for large-area rapid scanning, and narrow angle (such as 25°×19°) is suitable for long-distance precise detection.

3. Data storage and analysis

Storage function: whether it supports real-time photography and video recording, built-in storage space or external SD card (suitable for on-site inspection records).

Analysis software:

Can the supporting software generate temperature reports, heat distribution curves, and automatically mark abnormal points (such as FLIR Tools, Testo Thermal Imaging Software).

Whether it is compatible with cloud data management to facilitate team collaboration analysis (such as industrial Internet of Things scenarios).

III. Operation and environmental adaptability

1. Portability and battery life

Weight and size: Handheld devices are recommended to be ≤1kg, and ergonomic design (such as non-slip grips and rotatable screens) should be considered for long-term operations.

Battery life: continuous working time ≥4 hours, support fast charging or spare battery replacement (essential for outdoor operations).

2. Environmental protection level

Dustproof and waterproof: IP54 (splashproof) is suitable for daily use, and IP67 (short-term immersion in water) is suitable for harsh environments (such as firefighting and field search and rescue).

Working temperature: -20℃~50℃ is the normal range. For high temperature environment, high temperature resistant models should be selected (such as metallurgical industry needs to withstand ambient temperature above 100℃).

3. Additional functions

Laser ranging: The integrated ranging module can quickly calculate the target distance and assist in judging the intensity of thermal radiation (such as power inspection).

GPS positioning: Automatically mark the location of the detection point during outdoor operations to facilitate later data backtracking (such as photovoltaic power station inspection).

Voice annotation: Record the detection instructions on site to avoid omissions in text records (suitable for multi-person collaboration scenarios).

IV. Industry compliance and cost

1. Industry certification

Medical field: Medical device certification such as FDA and CE is required (such as medical infrared thermal imagers).

Explosion-proof environment: The petroleum and chemical industries need to select Ex explosion-proof certified models (such as ATEX and IECEx certification).

Metrological calibration: Industrial detection requires regular calibration, and brands that support traceability calibration services should be selected (such as FLIR and Testo provide official calibration).

2. Budget and cost-effectiveness

Entry-level: 5,000-20,000 yuan (240×180 pixels, basic temperature measurement function, suitable for home or small business).

Professional level: 20,000-100,000 yuan (640×480 pixels, fusion imaging, advanced analysis software, mainstream choice for industry).

High-end scientific research/military: more than 100,000 yuan (high resolution, customized functions, such as quantum well detector models).

Long-term costs: consider accessories (such as telephoto lenses, charging bases), software upgrades, calibration and maintenance costs.

V. Brand and after-sales service

1. Mainstream brand features

FLIR: Global leader, complete industrial and security product lines, and complete software ecosystem.

Testo: Focuses on industrial testing, easy to operate, suitable for rapid on-site diagnosis.

Seek Thermal: High cost-effective for consumer level, compatible with mobile phone APP (suitable for outdoor enthusiasts).

Guide Infrared/Dali Technology: Domestic high-end brand, civilianization of military technology, suitable for customized needs.

2. After-sales and technical support

Give priority to brands with local after-sales outlets to ensure convenient maintenance and calibration.

Ask whether training services are provided (such as thermal imaging principles, software operation), especially for first-time users.

Decision-making process suggestions

Clear requirements: first determine the purpose (such as "detecting hot spots on circuit boards" vs. "nighttime field search and rescue"), and exclude unsuitable models.

On-site testing: If conditions permit, use the target object for actual measurement (such as scanning a hot motor with a thermal imager) to observe the image clarity and temperature measurement accuracy.

Reference case: Equipment selection experience of peers (such as FLIR E8 is commonly used in power companies, and Testo 885 is often used for building inspection).

By screening in the above dimensions, the needs can be matched to the maximum extent to avoid waste due to insufficient parameters or redundant functions.